Major Industries That Depend on litho printing Today

Major Industries That Depend on litho printing Today

Blog Article

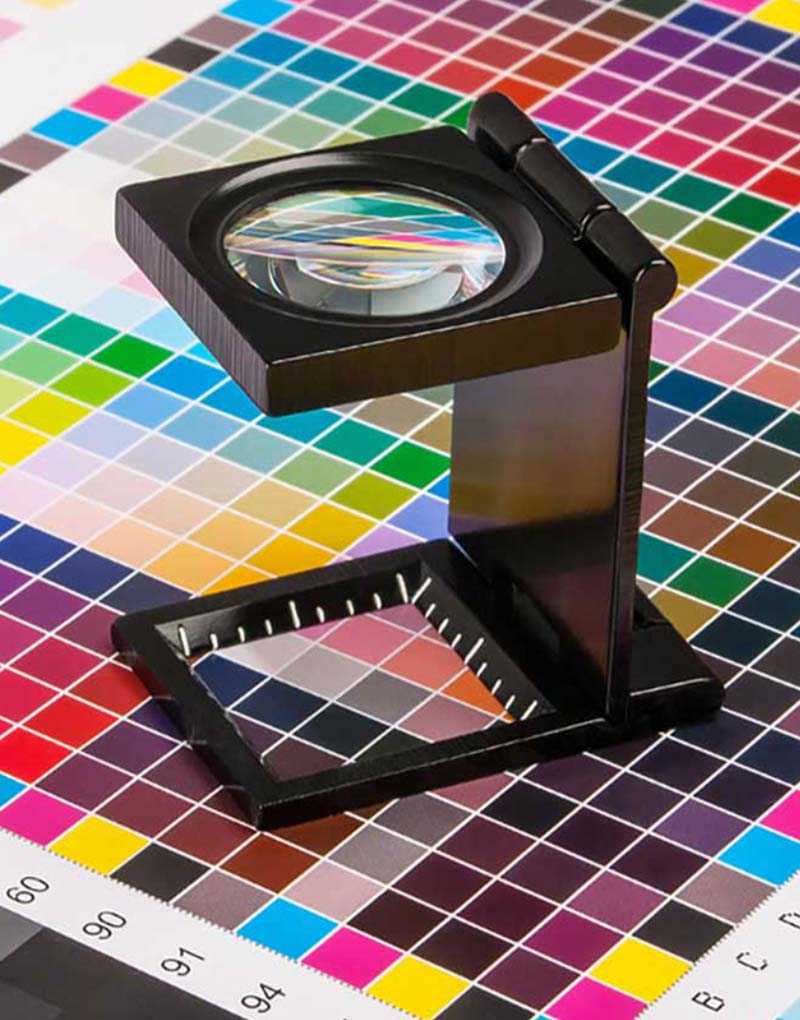

A Comprehensive Guide to Recognizing Litho Printing Strategies

The globe of litho printing, a strategy originating from the late 18th century, is a remarkable blend of history, technology, art and scientific research. This thorough guide will certainly decipher the complexities of this printing approach, from the make-up of litho inks to the challenges dealt with in contemporary applications. As we venture right into the complexities of lithography, the relevance of automation and sustainability in ensuring its future significance comes to be increasingly clear. Remain with us as we journey into the fascinating realm of litho printing.

The Historic Evolution of Litho Printing

The historical trajectory of litho printing, an essential technology in the realm of interaction, is a fascinating tale of human ingenuity. Birthed in the late 18th century by Alois Senefelder, this strategy was originally an economical approach of publishing staged jobs. Lithography, originated from the Greek words for 'stone' and 'to create', utilized a smooth rock surface area to transfer photos onto paper. The procedure developed with the introduction of the rotating press, which greatly raised efficiency (litho printing). In the 20th century, the innovation of countered lithography changed the market, permitting for automation of top notch prints. Each stage of litho printing's evolution showcases mankind's ruthless quest of efficiency and quality in visual interaction.

Decoding the Science Behind Litho Printing Inks

Moving on in the exploration of litho printing strategies, the focus now changes to the science behind litho printing inks. The structure of these inks, their drying out process, and shade mixing methods form the foundation of this complicated art type. Comprehending these aspects is vital to mastering the craft and accomplishing the preferred print results.

Structure of Litho Inks

In lithographic printing, the essential function of litho inks can not be overemphasized. Pigments, the color-providing elements, are finely ground bits put on hold in the vehicle, a liquid that lugs the pigment onto the printing surface area. Each component plays a vital component in the final print's top quality, making the specific formula of litho inks an intricate scientific research.

Ink Drying Refine

From the composition of litho inks, focus turns to the fascinating procedure of ink drying. The drying out procedure is crucial, as it impacts the last print's top quality and durability. 2 primary approaches are made use of in litho printing: oxidative drying and absorption. Oxidative drying involves the ink responding with oxygen in the air to form a hard, completely dry film. This technique offers a resilient coating, but can be slower compared to absorption. Absorption, on the other hand, involves the ink leaking right into the paper fibers, which is a quicker process but can cause less lively shades. The selection in between these methods depends on variables such as print speed needs, the paper type used, and the preferred surface.

Color Combining Strategies

While the drying out process plays a vital role in litho printing, the scientific research of color blending strategies holds equivalent significance. The scientific research behind litho printing inks additionally takes right into account the openness of the ink, which affects exactly how shades overlay and mix.

The Art and Style Components in Litho Printing

Litho printing takes a breath life right into art and design with its one-of-a-kind aspects. The procedure involves producing a photo on a lithographic limestone plate or steel plate with a smooth surface. The picture is after that published onto a medium, normally paper, by moving the ink from the plate. What sets litho publishing apart is its capacity to replicate detailed designs with high fidelity, making the outcome virtually identical to the initial art work. This is accomplished via making use of different line techniques such as hatching, stippling, and cross-hatching, which allow for a variety of tonal results. Furthermore, litho printing accommodates a range of colors, enabling artists to produce vibrant and dynamic prints. This mix of accuracy and versatility makes litho printing a preferred option for numerous musicians and developers.

Modern Applications of Litho Printing Strategies

Litho printing strategies have actually found extensive usage in the contemporary commercial market. Its influence and importance proceed to grow with the arrival of new innovations and modern technologies in the area. This area will explore these contemporary applications and the transformative role they play in the printing market.

Industrial Litho Printing Uses

In today's electronic age, one might question the importance of standard printing approaches. Yet, litho printing continues to be a vital component of the industrial field. High-volume printing tasks, such as the production of books, papers, and product packaging, count on litho printing for its capability to provide exceptional image top quality and cost performance. The process, which includes transferring a tattooed photo from a plate onto additional resources a rubber covering and after that to the printing surface, provides unmatched consistency. This makes it ideal for tasks needing a huge print run. Litho printing also find more offers a broad shade range, exceptional to that of digital printing. This makes it the best option for tasks that require vivid, premium shade recreation.

Innovations in Litho Printing

Pressing the limits of standard strategies, modern-day innovations have actually fueled a host of developments in litho printing. One popular advancement is digital litho printing, which integrates the virtues of electronic modern technology with litho's high-grade outcome. These developments underscore the enduring relevance of litho printing in the modern-day globe.

Discovering the Process of Litho Printing: Detailed

Challenges and Solutions in Contemporary Litho Printing

Regardless of the accuracy and practice that litho printing proudly supports, it is not without its collection of contemporary difficulties. The most widespread issues consist of the high first setup expense, problem in printing variable data, and environmental problems due to chemical usage. Solutions are arising as modern technology advances. Digital litho printing permits for cost-effective brief runs and simple modification, addressing the problem of variable information. Environmentally-friendly inks and more secure plate-making processes mitigate environmental worries. In addition, developments in automation have actually reduced labor prices, additionally democratizing the lithography process. Thus, while there are challenges, the litho printing sector is proactively adapting to satisfy them head-on, ensuring its significance in the future.

Verdict

In conclusion, litho printing, with its abundant background and clinical details, holds a substantial location in the print market. As the guide reveals, it's a synthesis of art and innovation, with modern-day advancements guaranteeing its significance. The market encounters difficulties that call for cutting-edge remedies, with a focus on automation and sustainability. The future of litho printing pivots on its capability to adjust to these changing needs, affirming its enduring value in an advancing market.

Report this page